Digitization of Refineries at the Cosmo Energy Group

Strengthening Competitiveness of Our Oil Business and Pursuing Low Carbonization

Digitization of Refineries at the Cosmo Energy Group

Strengthening Competitiveness of Our Oil Business and Pursuing Low Carbonization

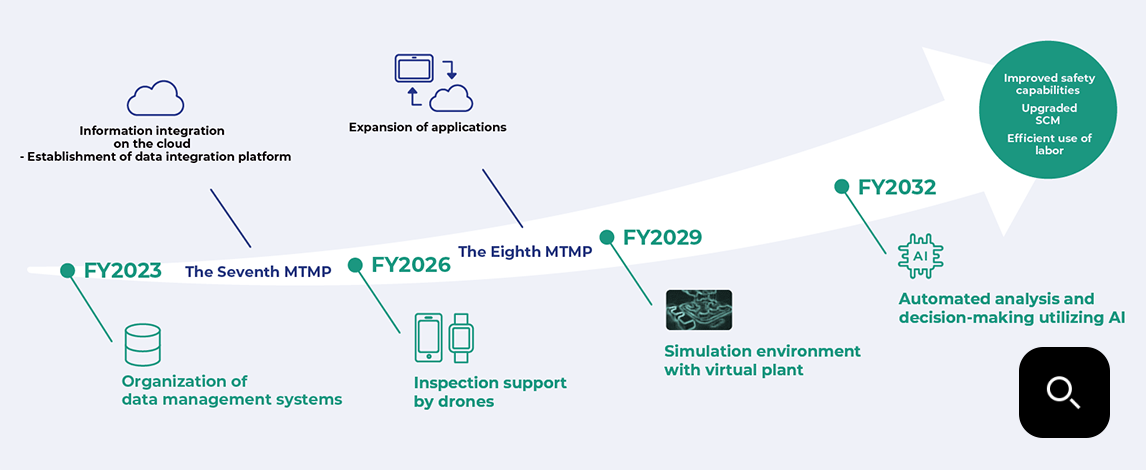

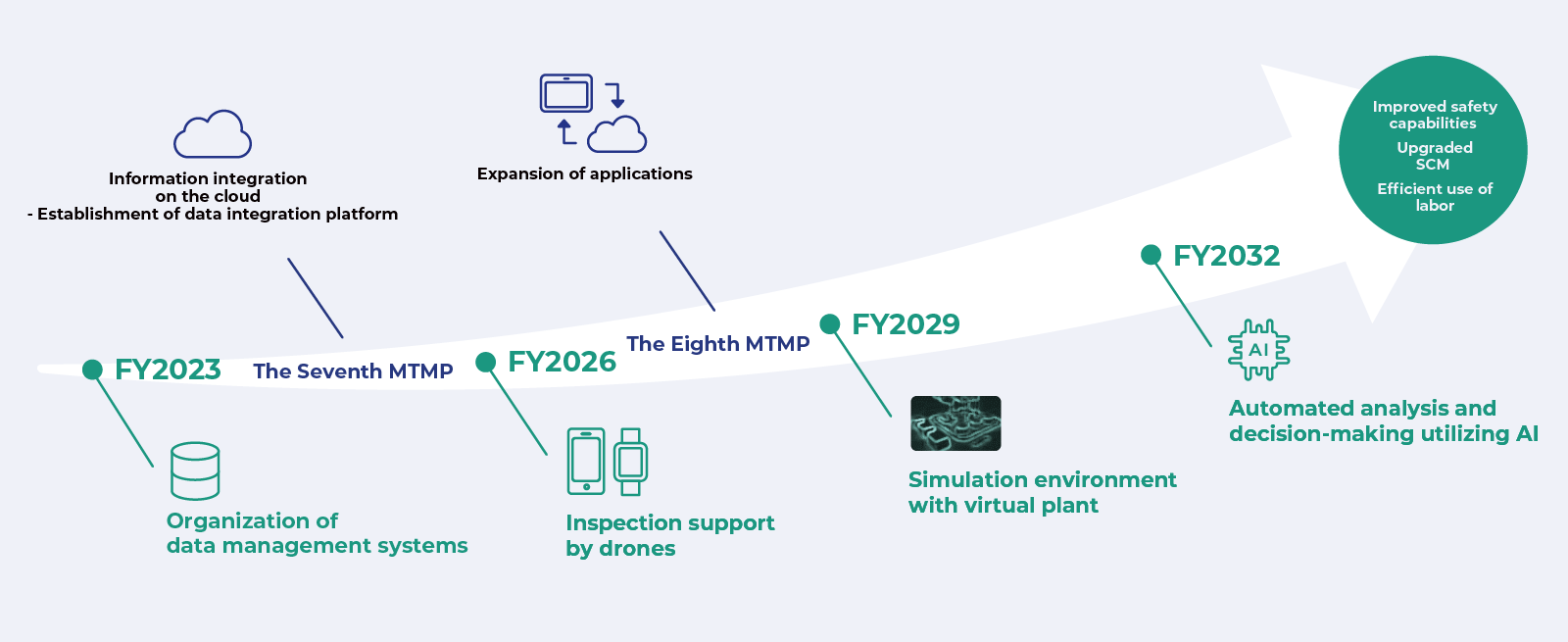

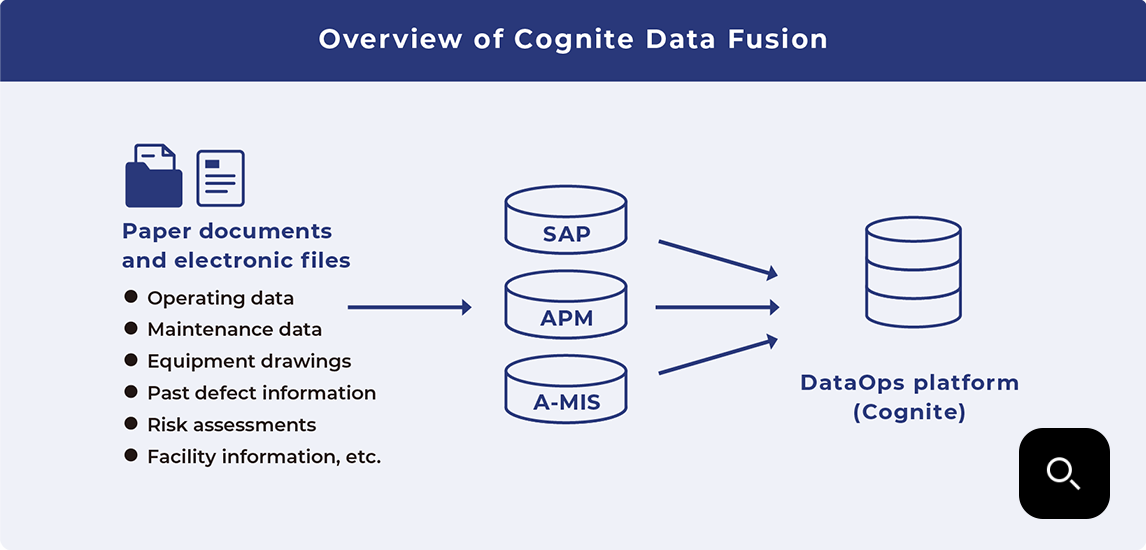

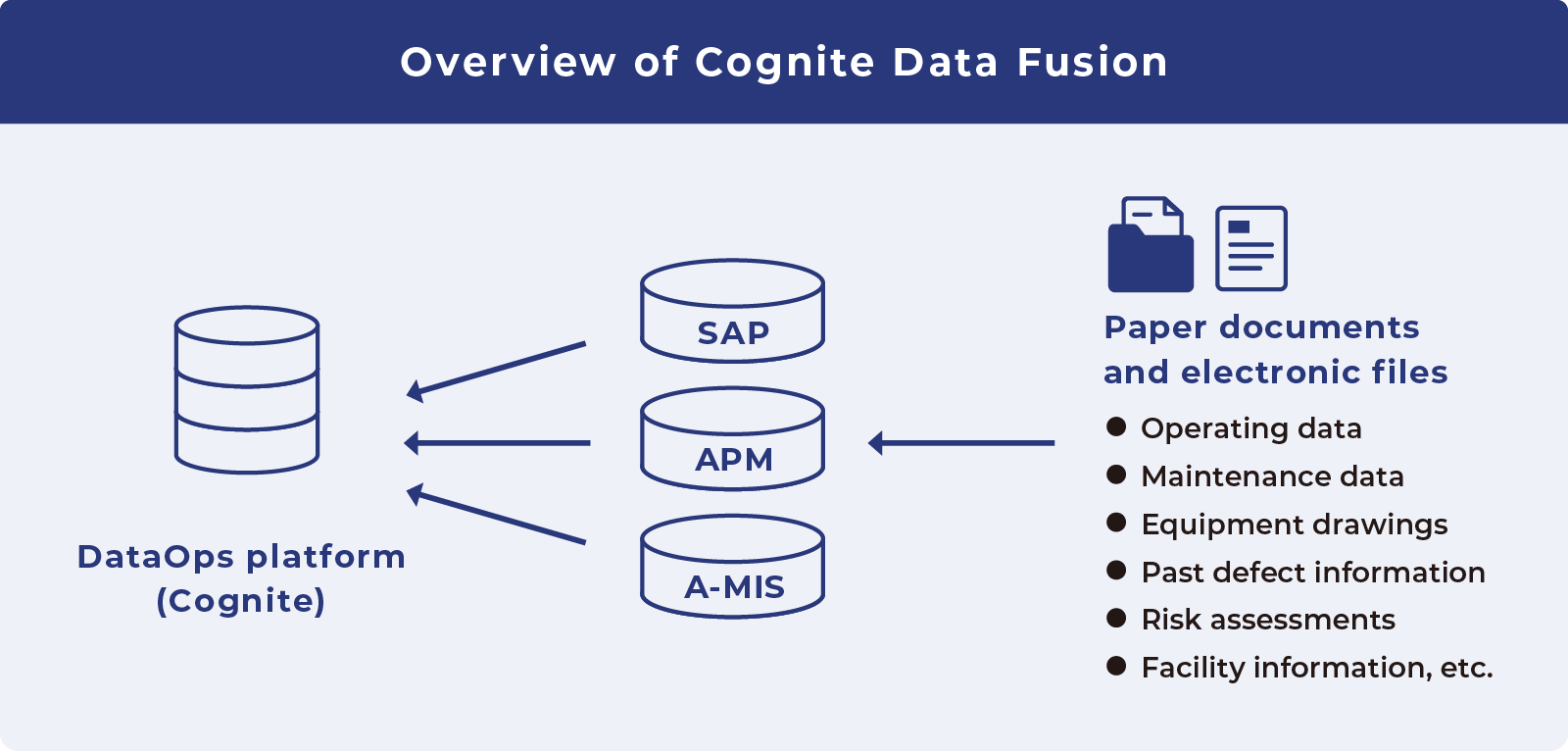

As part of our efforts to strengthen the competitiveness of our Oil Business (specifically enhancing refinery competitiveness), the Cosmo Energy Group is promoting a shift to high-efficiency operations by digitizing our refineries. In May 2024, we introduced Cognite Data Fusion® (CDF), an industrial DataOps platform provided by Cognite, at all refineries. This has enabled the centralized management of various information, including drawings, equipment inspection records, operating data, and maintenance plans.

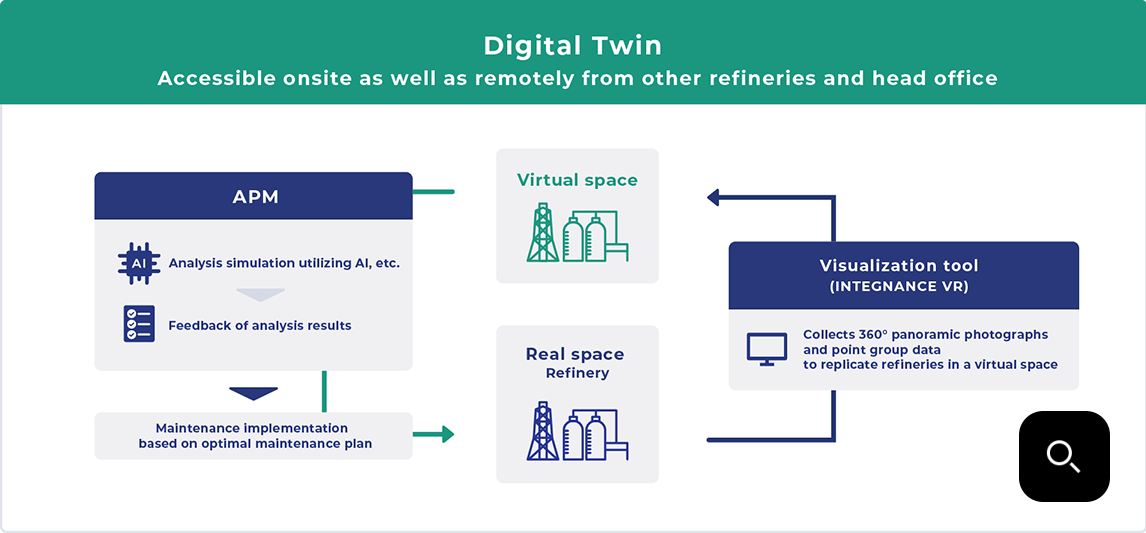

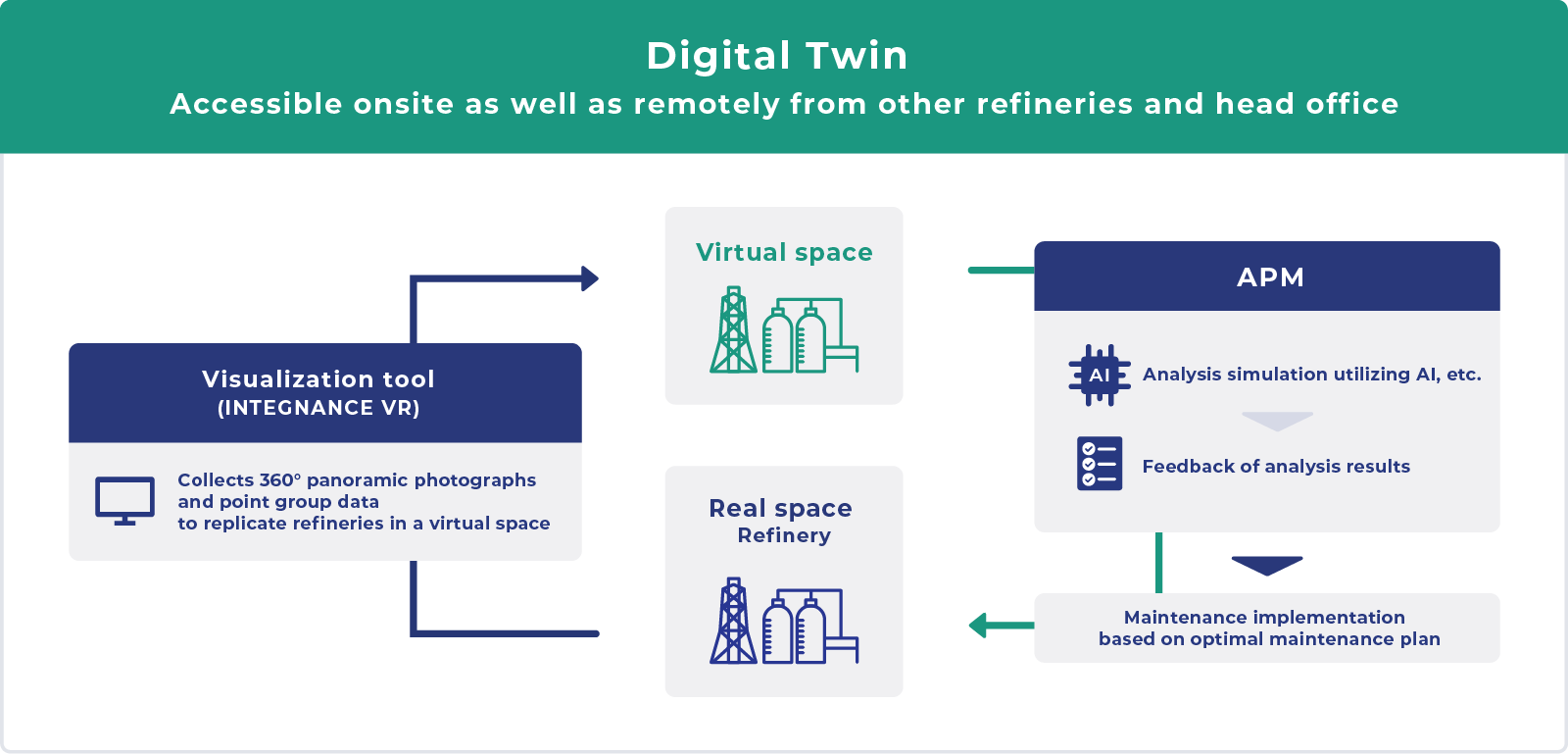

Simultaneously, the Group is advancing the development and operation of an Asset Performance Management (APM) System to facilitate the integrated management and advancement of maintenance strategies. Additionally, we are building digital twins to replicate our plants in a virtual space, aiming for full implementation by 2025.

Initiatives to Integrate Plant Data

Challenges in Data Management at Refineries

At refineries, engineers had been spending a significant proportion of their time—as much as 70-80%—on data collection alone as part of the data collection, organization, and decision-making process.

For example, when equipment defects arose, engineers needed to collect various data from different sources, including:

・Drawings and facility information

・Inspection records

・Operating data

・Maintenance plans, etc.

Introduction of CDF DataOps Platform

In August 2023, to address these challenges and improve productivity, the Cosmo Energy Group decided to introduce Cognite Data Fusion® (CDF), a DataOps platform provided by Cognite to facilitate centralized data management, across all refineries.

As a result, various types of data, previously scattered across paper documents and electronic files, can now be consolidated into CDF.

Digital Plant Introduction Video ~ Cross-Organizational Utilization of Data and Application of Generative AI~

Video provided by Cognite

*SAP: An integrated business management system

*APM: A system for assessing facility and equipment risks and overseeing, managing, and advancing our maintenance strategies

*A-MIS: An inspection support system

Integrated Monitoring to Support Real-Time Maintenance

Cosmo Oil is working to upgrade its maintenance operations by further leveraging plant data integrated via the CDF DataOps platform. At the core of this effort is the Reliability Center of Excellence (RCoE)—an integrated monitoring room that centralizes maintenance functions. By centrally managing equipment data and operational knowledge from the Chiba, Sakai, and Yokkaichi refineries, the RCoE enables real-time condition monitoring and swift responses, contributing to greater equipment reliability and stable operations.

Integrated Monitoring Room Supports Next-Generation Maintenance Operations

Video provided by Cognite

Leveraging a Visualization Tool

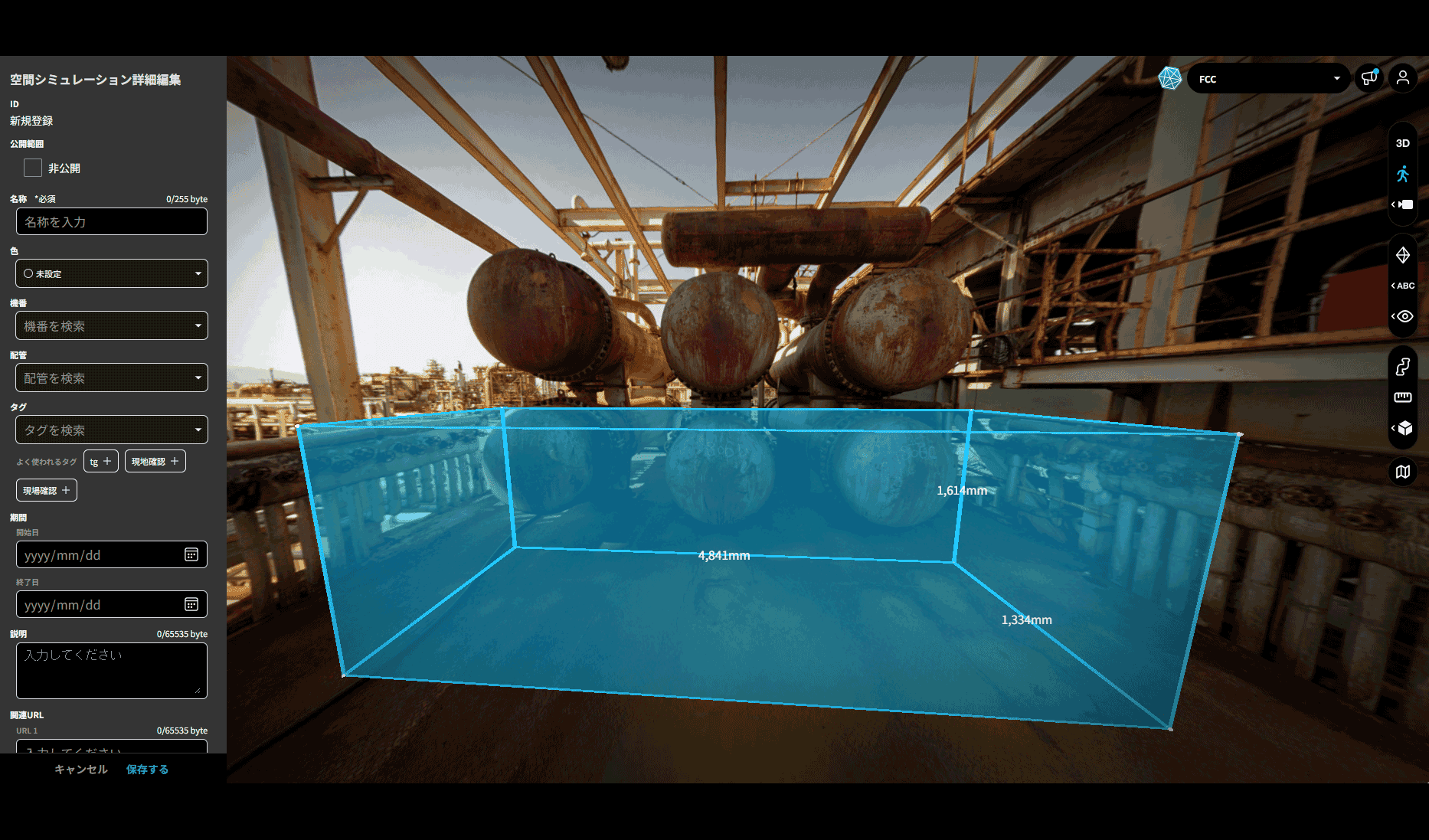

Digital Twin (VR)

A digital twin integrates multiple technologies to replicate real-world refineries in a virtual space—like a twin—utilizing data collected from plants. The integration of data on CDF enables remote access to the digital twin using virtual reality (VR).

With centralized data management and the ability to monitor sites via VR-driven digital twins, the time previously spent on data collection has been significantly reduced, leading to improved operational efficiency.

360°panoramic photograph viewed using VR

Hover over each facility or piece of equipment to view linked drawing data and other related information

COSMO’s Asset Performance Management (APM) System

Aging Refineries and the Importance of Maintenance Plans

Much of the equipment at refineries has been in operation for over 50 years. Unplanned shutdowns due to aging-related problems have become a major challenge, making maintenance plans to prevent such occurrences extremely important.

Until now, maintenance plans have been developed by employees on paper or using tools such as Excel, with experience and skill being critical for effective maintenance.

Increasing Maintenance Efficiency Through the Introduction of an APM System

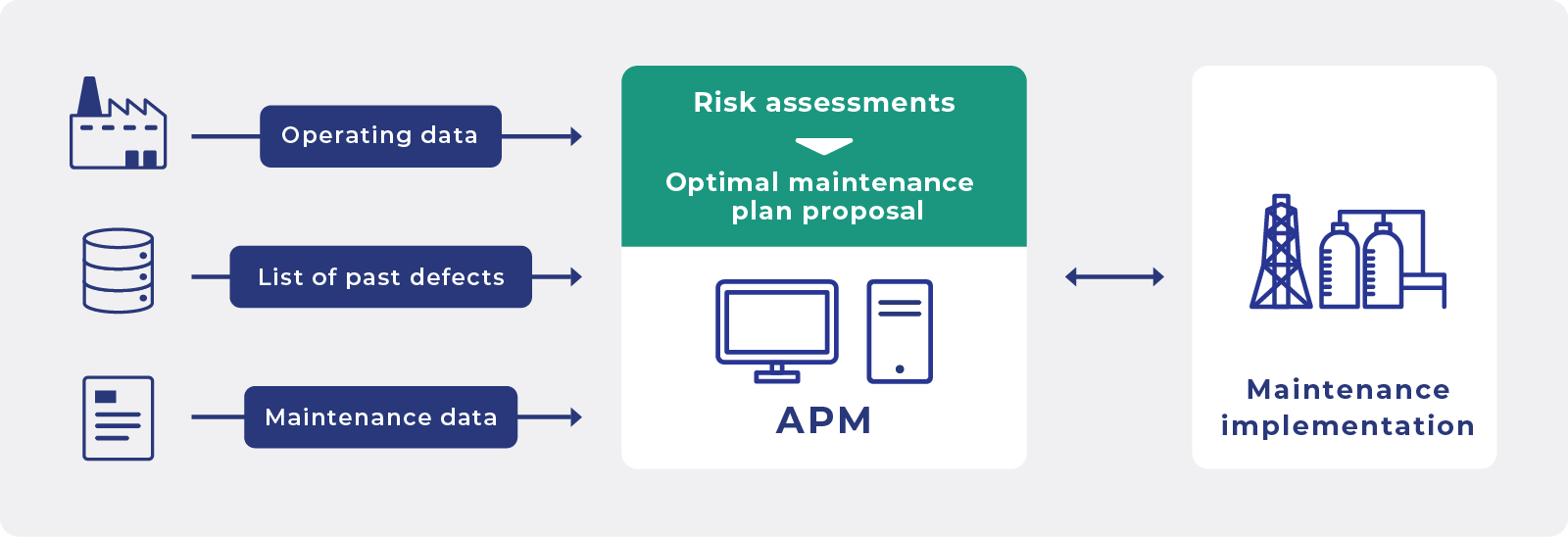

Since FY2023, an Asset Performance Management (APM) System, developed by GE Vernova Power & Energy Resources Software, has been introduced at the Chiba and Sakai refineries to increase the efficiency and accuracy of our maintenance approaches.

The APM System utilizes globally recognized technical information to assess equipment risks and serves as a system for the integrated management and advancement of our maintenance strategies.

Improvements in Equipment Performance and Results

By conducting quantitative risk assessments as well as developing and analyzing highly effective maintenance plans, the system comprehensively monitors equipment performance, leading to the prevention of defects.

In the approximately one year since we started utilizing data provided by the APM System, the refinery utilization rate has improved by 1.3%, and we have been able to confirm that this contributed to the high uptime of our refineries.

In their feedback, refinery staff noted that they were able to confirm multiple instances where defects were preemptively prevented, while others commented that the system enables the monitoring of corrosion rates that would be impossible for humans to track.

In FY2023, the combined utilization rate of crude distillation units (CDU) across the three refineries was 87.9%. Moving forward, we remain committed to maintaining a high utilization rate.

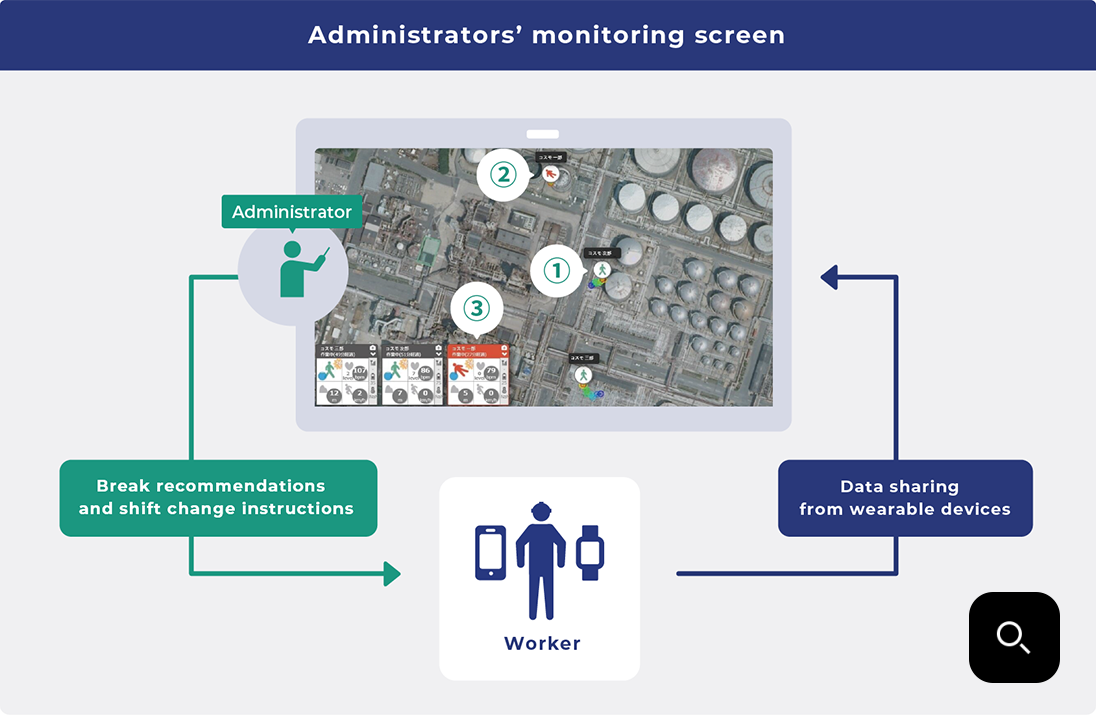

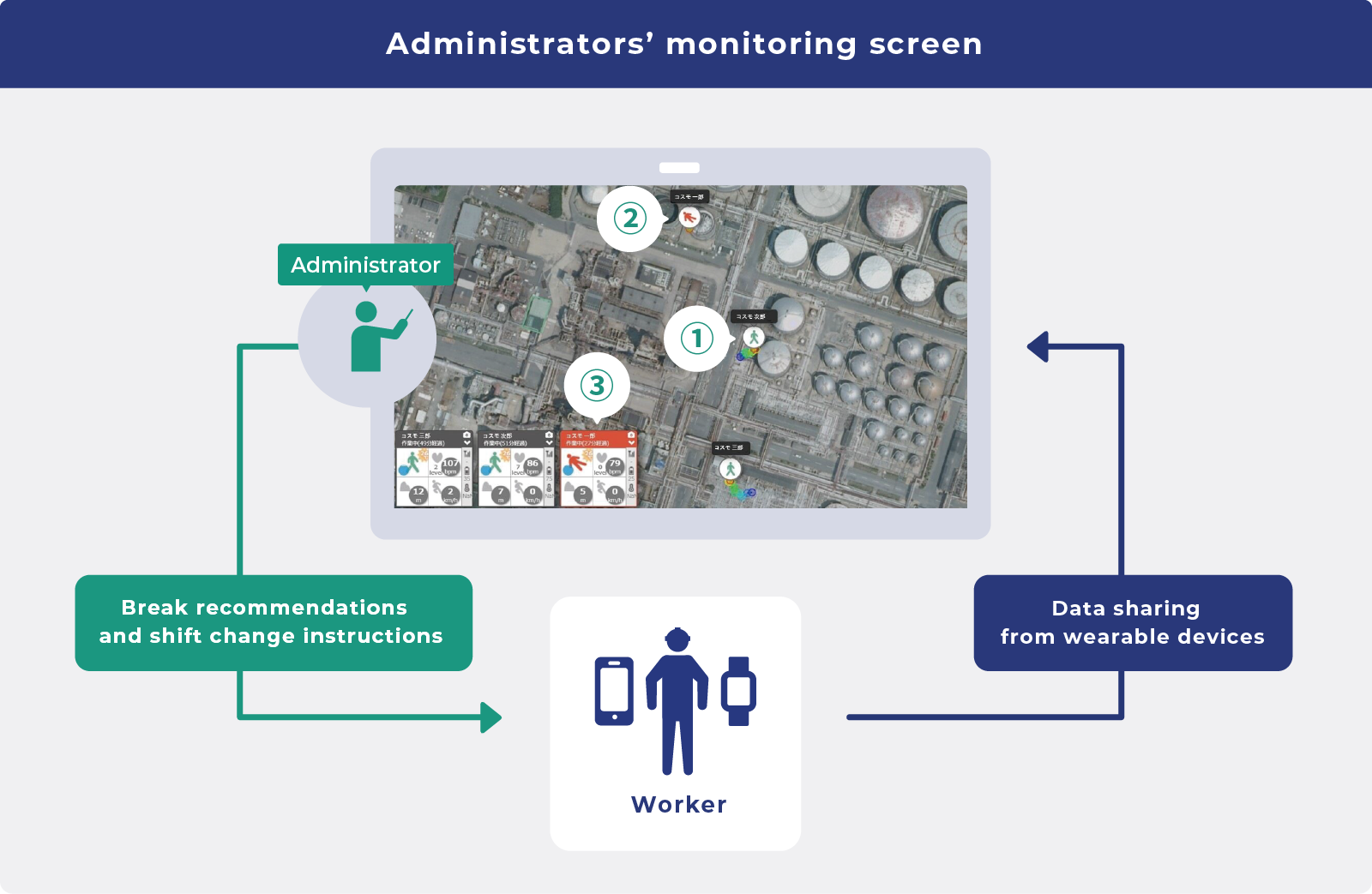

Digitization of Safety Measures

Enhancing Occupational Safety with the "Anzen Mimamori-kun" Vital Sensor

To prevent heatstroke and work-related accidents among field workers and ensure prompt intervention, the Cosmo Energy Group began introducing the "Anzen Mimamori-kun" vital sensor in FY2023.

The system utilizes wearable devices to allow supervisors to monitor workers' location and vital signs in real time.

Key features:

Location monitoring via GPS tracking

Detection of serious work-related accidents

Heatstroke prevention based on Wet Bulb Globe Temperature (WBGT; a measurement of heat stress) and heart rate elevation

With these capabilities, "Anzen Mimamori-kun" enables the early detection of abnormalities in field workers and ensures prompt intervention.

The system has already been introduced at the Yokkaichi Refinery and is gradually being implemented at the Chiba and Sakai refineries. With this, the "Anzen Mimamori-kun" is now operational across all Cosmo Energy Group refineries.