“In striving for harmony and symbiosis between our planet, man and society, we aim for sustainable growth towards a future of limitless possibilities.” In order to realize this Cosmo Energy Group Management Vision, we recognize environmental issues such as natural capital and biodiversity as important issues alongside climate change. Our aim is to be an environmentally responsible energy group that practices “harmony and symbiosis with the global environment,” which is part of our Basic Concept of Sustainability. This is why Cosmo Energy Group Code of Conduct states that we will proactively and continuously pursue the utilization of clean energy and strive to preserve the global environment. We also have an Environmental Policy in place to ensure that all of our business activities are conducted in harmony with the environment.

Cosmo Energy Group’s Environmental Management System

The Group’s Sustainability Strategy Council is chaired by the executive officer in charge of the Sustainability Initiative Department. Under the supervision of the executive officer, the Sustainability Initiative Department manages the progress of the Group’s environmental activities. This includes the Group’s efforts to address climate change, as specified in the long-term vision and the Consolidated Medium-Term Management Plan. The department also identifies issues and devises appropriate measures, which are submitted to the Sustainability Strategy Council as proposed agenda items. The executive officer in charge of the Sustainability Initiative Department is responsible for implementing environmental measures such as efforts to address climate change. When decisions are made regarding these measures, they are discussed by the Executive Officers’ Committee, and the final responsibility is borne by the Group CEO, who chairs the Executive Officers’ Committee.

The members of the Sustainability Strategy Council include executive officers appointed to serve by the council chair, the general manager of the Corporate Planning Department of Cosmo Energy Holdings, as well as the executive officers in charge of sustainability at the core operating companies (Cosmo Oil, Cosmo Oil Marketing, and Cosmo Energy Exploration & Production). The full-time Audit and Supervisory Committee member also attends these meetings as an observer. This membership structure allows the council to incorporate objective perspectives.

The Sustainability Strategy Council deliberates on important operations and policies related to environmental issues. Matters deemed to have a major impact on the entire Group are determined via discussion and then reported to the Executive Officers’ Committee and the Board of Directors, thereby ensuring appropriate oversight by the senior management team.

In fiscal 2024, the Sustainability Strategy Committee1 reported to the Board of Directors on important matters related to climate change, including an assessment of greenhouse gas (GHG) emission reduction target results, as well as TCFD-related initiatives. This information was also shared with Group companies via Sustainability Liaison Committee meetings to ensure coordination across the entire Group.

The Group’s main business sites which have a significant impact on the environment — eight sites, including refineries — have obtained ISO 14001 certification. In addition to internal audits, the Group’s business sites also undergo external reviews to assess not only compliance with relevant laws and regulations, but also to determine whether initiatives are being implemented to reduce environmental impact on air and water.

1. On April 1, 2025, the Sustainability Strategy Committee was replaced by the Sustainability Strategy Council.

ISO 14001(environmental management systems) Certified Sites

| Site name | Acquisition date | Renewal date |

|---|---|---|

| Chiba Refinery, Cosmo Oil Co., Ltd. | March 1998 | March 2024 |

| Yokkaichi Refinery, Cosmo Oil Co., Ltd. | March 1998 | March 2025 |

| Sakai Refinery, Cosmo Oil Co., Ltd. | March 1998 | March 2025 |

| Cosmo Matsuyama Oil Co., Ltd. | December 1988 | December 2022 |

| Chiba Plant, Maruzen Petrochemical Co., Ltd. | November 1999 | November 2023 |

| Yokkaichi Plant, Maruzen Petrochemical Co., Ltd. | December 2001 | December 2022 |

| Shimotsu Plant, Cosmo Oil Lubricants Co., Ltd. | June 2003 | June 2024 |

| Osaka Plant, Cosmo Oil Lubricants Co., Ltd. | October 2003 | July 2023 |

Safety and environmental inspections are conducted at least once a year at Cosmo Oil’s Chiba, Yokkaichi, and Sakai refineries, as well as at Cosmo Matsuyama Oil. They are also conducted at least once every two years at Cosmo Oil Lubricants’ Shimotsu and Osaka plants.

Moreover, Maruzen Petrochemical’s Chiba and Yokkaichi plants carry out environmental and safety audits at least once a year.

Service Station Environmental Management

Thorough Soil Monitoring and Response Measures

We conduct regular soil surveys at Cosmo Energy Group business sites and service stations to prevent soil contamination and ensure a quick and proper response in the event of any oil leakage. We also conduct soil remediation and monitoring in response to environmental impacts, as needed.

In fiscal 2024, 25 soil surveys were conducted and 2 soil remediation project was completed.

As of the end of March 2025, a total of 1,205 service stations had been surveyed since 2001.

Preventing Underground Tank Leaks

Based on the revision of Japan’s Fire Service Act in June 2010, underground fuel storage tanks installed 40 or more years ago were required to be reconditioned. We have completed the applicable rehabilitation processes at all service stations owned by the Group. For those owned by distributors, our sales representatives are providing them with the necessary support to determine the deadlines for underground tank rehabilitation and to prevent underground fuel leaks.

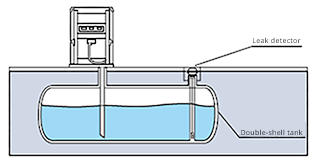

At new service stations, we are installing equipment that has an extremely low risk of leakage, such as double-shelled fuel tanks to prevent leaks and resin piping that does not corrode. We are also making equipment improvements at older stations, such as updating and strengthening piping materials and taking measures for electrical corrosion protection, to suit the needs of situation.

Double-shell tank

For the number of environmental accidents and our compliance with environmental laws and regulations, please see “Number of environmental accidents” in ESG Data.